Description

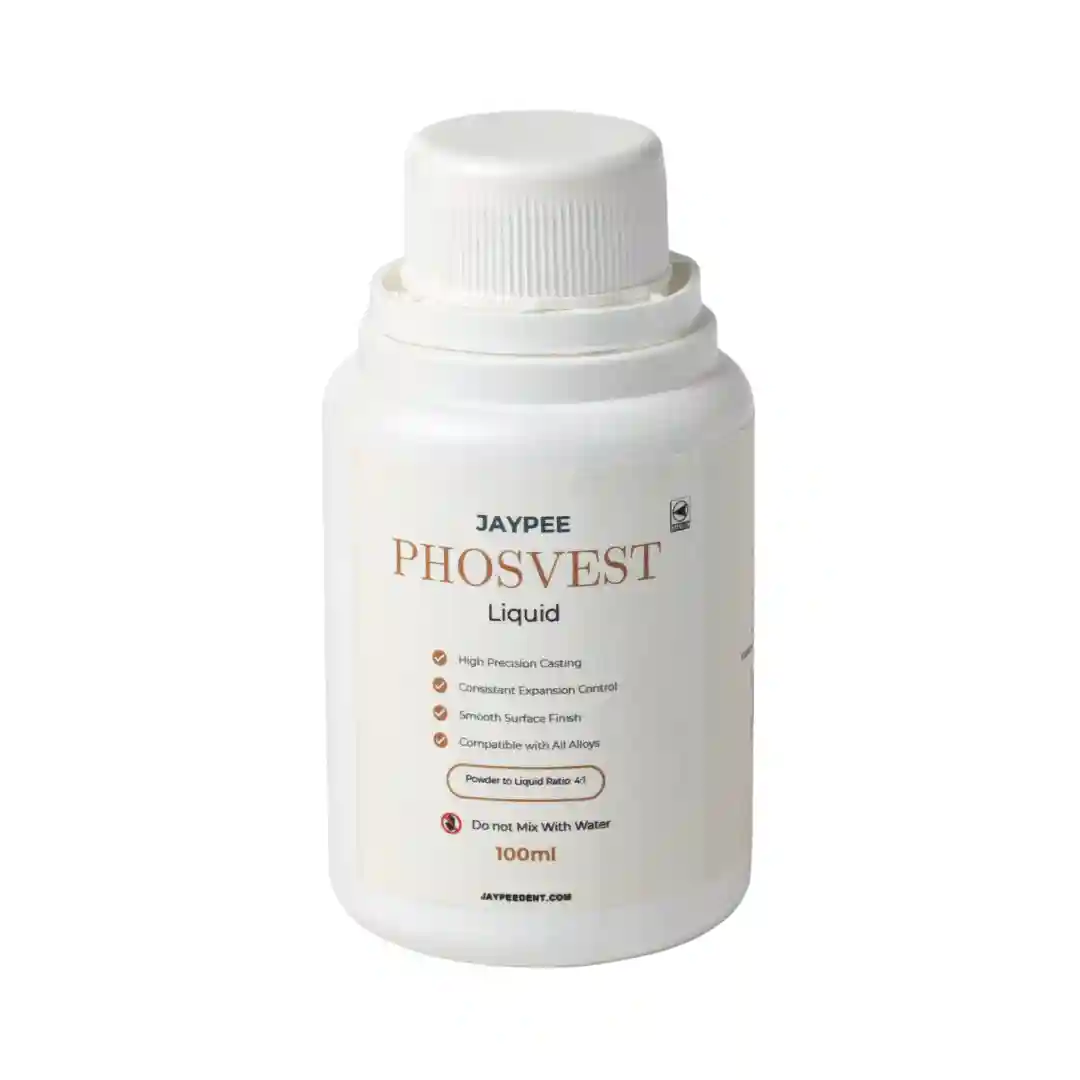

Features of Jaypee Phosvest Phosphate Bonded Investment Powder, For Dental Casting, Powder 400g and Liquid 100ml

- High precision casting

- Consistent expansion control

- Smooth surface finish

- Compatible with all alloys

Instructions for Use

-

Don’t mix with water

- Always use only the specified Jaypee Phosvest liquid.

- Water or other substitutes will compromise performance and dimensional accuracy.

-

Use silicone rings only

- Metal rings are strictly prohibited as they restrict proper expansion of the material and can result in distorted castings.

-

Furnace loading procedure

- Place the filled ring into the furnace at room temperature (max 100°C).

- Do not preheat the furnace before placing the ring.

- Gradually raise the temperature to 900°C.

- Hold at 900°C for 10 minutes tom allow complete burnout.

-

Mixing instructions

- Recommended powder to liquid ratio is 4:1 by weight.

- Use a vacuum mixer for best results and reduced porosity.

- Mix thoroughly for 30-60 seconds depending on batch size.

-

Storage guidelines

- Investment powder must be stored in a dry, airtight container.

- Do not leave packets open, as the powder is highly hygroscopic and will absorb moisture from the air.

- Moisture contamination can render the powder unusable.

-

Work environment

- Work in a clean, dry environment to prevent contamination.

- Avoid working in areas with high humidity or condensation.

-

Shelf life

- Use the powder before the expiry date mentioned on the packaging.

- Improper storage may reduce shelf life and performance.